Role of IoT in Material Handling Equpment

In today’s fast-paced industrial landscape, the integration of the Internet of Things (IoT) is revolutionising the way businesses maintain and manage their Material Handling Equipment (MHE). IoT-driven predictive maintenance ensures improved efficiency, reduced downtime, and cost savings, making it an indispensable tool for modern industries.

Challenges in Conventional Mode of Service in MHE

Despite regular scheduled maintenance, unexpected failures in material handling equipment can still occur due to factors like poor work environments, worn-out components, extended operation hours, excessive loads, and operator errors. Such failures disrupt the supply chain, resulting in increased downtime, higher maintenance costs, and reduced operational efficiency.

Another major challenge is the time taken to diagnose the problem. A service team must visit the repair site, dismantle the machine, and manually identify the issue, further delaying the resolution process.

These challenges can be effectively addressed by implementing IoT in material handling equipment.

Understanding IoT in Material Handling Equipment

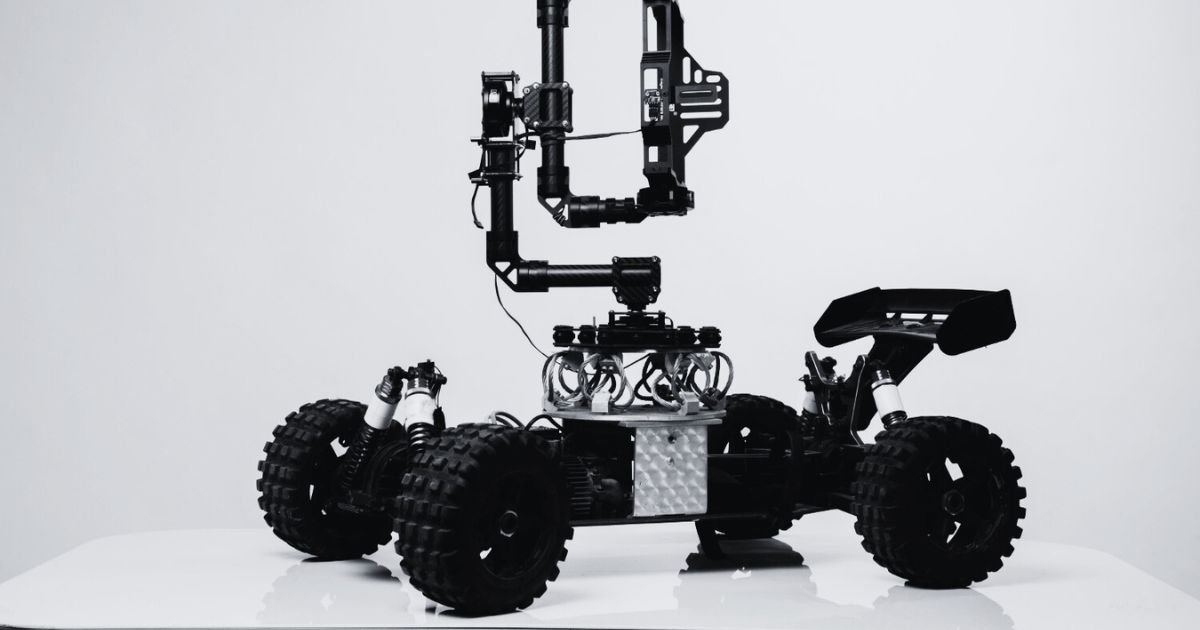

IoT refers to a network of interconnected devices that collect and exchange real-time data. In the material handling sector, IoT sensors are embedded into Forklifts, Pallet jacks, Stackers, and Automated Guided Vehicles (AGVs) to monitor performance, detect potential issues, and optimise operations.

Benefits of IoT in MHE Maintenance

- Predictive Maintenance for Reduced DowntimeTraditional maintenance methods rely on routine checks or reactive repairs after a failure occurs. IoT-enabled predictive maintenance uses real-time data from sensors to detect wear and tear, allowing businesses to address issues before they lead to breakdowns. This minimises unexpected downtime and extends the lifespan of equipment.

- Real-Time Performance Monitoring

IoT systems continuously collect and analyze operational data such as temperature, pressure, vibration, and fuel consumption. By monitoring these parameters, companies can ensure their equipment runs at optimal performance levels, preventing inefficiencies and safety risks. - Cost Savings and Improved ROI

Unplanned maintenance and emergency repairs can be costly. IoT-driven maintenance strategies help businesses cut down repair expenses, optimize labor allocation, and reduce overall maintenance costs. By investing in predictive analytics, companies can significantly improve their return on investment (ROI). - Remote Diagnostics and Troubleshooting

With IoT, maintenance teams can diagnose problems remotely, reducing the need for on-site inspections. If an issue arises, technicians can assess the situation in real time and provide quick solutions, minimizing operational disruptions. - Enhanced Safety and Compliance

Material handling equipment failures can lead to workplace accidents and compliance violations. IoT helps ensure adherence to safety standards by continuously monitoring critical safety parameters. Alerts and automated shutdowns can be triggered if potential hazards are detected, creating a safer work environment.

Implementation of IoT in MHE Maintenance

For businesses to fully leverage IoT in material handling equipment maintenance, they need to:

- Install Smart Sensors: Equip forklifts, conveyors, and AGVs with IoT sensors to track real-time data.

- Utilize Cloud-Based Platforms: Store and analyze data for actionable insights using IoT-powered dashboards.

- Integrate AI and Machine Learning: Enhance predictive analytics to make more accurate maintenance predictions.

- Train Workforce: Ensure employees understand IoT tools and their benefits to streamline adoption.

Vizai Engineering provides innovative and cost effective IoT solutions for the Material Handling Equipments, integrated with data analytics tools to precisely monitor the Key Performance Indicators.

We are searching IOT for MHE movement tracking purposes.

Please detail your requirement to our email at contact@vizaiengineering.com. Thanks